Measure CO2 levels reliably with CO2 sensors

When lots of people share a room, the air can get stale. This is mostly caused by exhaled carbon dioxide (CO2). The results are: Reduction in well-being, concentration and performance.

Theben CO2 sensors monitor CO2 levels in schools and classrooms, in offices and meeting rooms or in passive and low-energy buildings. CO2 sensors thereby make a decisive contribution to indoor air quality.

This site contains comprehensive information on CO2 levels in indoor air and their effects as well as needs-driven and energy-efficient ventilation control using CO2 sensors.

Contents:

- Background: Increased CO2 levels and their consequences

- Sites: CO2 sensors in schools, offices, passive and low-energy houses

- Ventilation control: CO2 sensors for appropriate ventilation control

- Measurement method: Non-dispersive infra-red

- Downloads and further information

Background: Increased CO2 levels and their consequences

We all know about badly ventilated houses, stuffy classrooms and meeting rooms. In addition to humidity and temperature, this is mainly due to exhaled carbon dioxide. An odourless and tasteless gas that is only detected by human beings due to its negative characteristics: feeling unwell, lack of concentration and deterioration in performance.

Human beings absorb oxygen from the air when they inhale and release carbon dioxide into the air when they exhale. Inhaled air contains 21% oxygen and 0.035% carbon dioxide. In contrast, exhaled air contains just 16% oxygen and 4% carbon dioxide. While carbon dioxide is only harmful to human beings at concentrations of 2.5% and above, performance levels, concentration and well-being are adversely affected at a concentration of 0.08% (800 ppm).

After just a few minutes, carbon dioxide levels reach 5,000 to 6,000 ppm in enclosed spaces like classrooms, offices or meeting rooms where people often congregate and which are subject to restricted ventilation. Theben CO2 sensors measure CO2 levels reliably. The measured values serve as an indicator for the ventilation control to increase the intake of fresh air.

Excursus: Max von Pettenkofer makes room air quality measurable

Max von Pettenkofer (3. December 1818 to 10. February 1901) was a professor of medical chemistry at the Ludwwig Maximilian University Munich and the first German professor of hygiene from 1865. With his studies on carbon dioxide levels 140 years ago, he laid the foundation for our current regulations relating to air quality (DIN-1946-2). This standard sets an upper CO2 limit of 1,500 ppm. That means there should only be 1,500 CO2 molecules per million air particles.

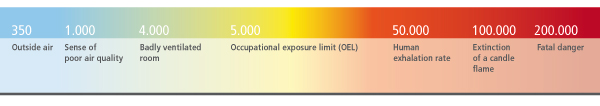

| CO2 level |

|

|

| Caption: Typical CO2 levels (in ppm) and their affect on human beings. |

1,000 ppm CO2 – the threshold for good indoor air quality

Really good indoor air quality does not exceed a threshold of 1,000 ppm CO2. Therefore, DIN 1946-6 requires an outdoor air flow of 30m3/h per person. A carbon dioxide level of 1,000 ppm CO2 is not achievable by occasional ventilation or opening windows given modern building standards and the thickness of the outer shells of buildings. It is often the case that windows in public buildings such as schools, classrooms or large offices cannot be opened: Good indoor air quality can only be guaranteed in such cases by using a ventilation system controlled by a CO2 sensor.

Application: CO2 sensors in schools, offices, passive and low-energy houses

Due to statutory provisions a needs-driven input of fresh air to modern buildings such as passive and low-energy houses is essential to avoid health risks and damage to buildings over the long term. This is where Theben CO2 sensors come into play: CO2 sensors measure the relative humidity in buildings as well as CO2 levels If set values are exceeded, CO2 sensors such as AMUN 716 KNX send a signal to the building automation system, e.g. KNX, and the ventilation system draws in more fresh air or opens windows automatically. Conventional control is also possible with Theben CO2 sensors such as AMUN 716 R: It directly controls the ventilation system.

Ventilation control: CO2 sensors for needs-driven ventilation control

Together with modern building systems technology such as KNX, CO2 sensors make an enormous contribution to saving energy. Ventilation is a matter of guesswork without CO2 sensors. And that's mostly too late or too much. Too much in this context means heat and heating costs are lost with the exchange of air. This is where Theben CO2 sensors come to the fore: The readings of the CO2 sensor show when, and for how long, ventilation is required. The ventilation system only introduces fresh air as long as it is actually required. In addition to the heating energy saved, speed-controlled ventilation via CO2 sensors also offers large potential savings with fans in ventilation systems. The output of a fan depends on the third power of its speed. A reduction in speed of 20% leads to the halving of electricity consumption.

Volume flow |

|

|

| Caption: CO2 sensors enable great potential savings in energy costs (green surface). |

Measurement method: Non-dispersive infrared process

Theben CO2 sensors measure CO2 levels via infrared spectroscopy, also known as non-dispersive infrared process (NDIR). As CO2 reduces the incidence of infrared light on the CO2 sensor, the received signal changes in relation to the CO2 levels in the indoor air.

Further information on Theben CO2 sensors:

Download brochures, catalogues and planning aids:

Service Hotline

Our hotline is available to help you with any questions about CO2 sensors:

Our hours of operation

Monday to Thursday: 7 a.m. to 6 p.m.

Friday: 7 a.m. to 4 p.m.

During off-service hours you can contact our hotline: hotline@theben.de or fax to +49 (0)7474/692-207